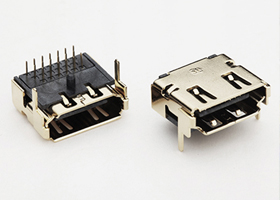

The use of contact plating for the connector

Connector is an important component in the electronic components industry, electronic engineering and technical personnel must not difficult to find: most of the connectors are coated with a layer of special coating. Most people have a common thing in mind the doubts, connectors coated with any special significance? The contact plating of the connector not only protects the connector from corrosion by the environment, increases the durability and wear resistance of the connector, it also helps to establish and maintain a stable connector impedance from electrical performance. Specifically in:

1, the connector coating anti-corrosion function

The first thing to consider for the connector is corrosion protection. Most electrical connector contact pads are made of a copper alloy which is susceptible to corrosion, such as oxidation and vulcanization, in a typical electrical connector operating environment. Actually, the contact plating is used to close the contact spring from the working environment to prevent corrosion of the copper. Of course, the coating material must not be damaged (at least within the harmful range) in its working environment. As an important function of corrosion protection at the same time, optimize the interface is to choose the appropriate contact plating material considerations.

2, the connector coating to help improve mechanical properties

The parameters related to the mechanical properties mainly affect the durability or wear of the coating, as well as the factors of the combining force. These factors are considered in the same basic effect of two different views, that is, multi-point contact interface in the relative motion of the process of cold welding to share. The most important mechanical properties include hardness, ductility and friction coefficient of the coating material. All of these properties depend on the inherent nature of the coating material and the working process used.

3, the connector coating to help improve electrical performance

The optimization of the electrical properties can be considered from the control of the films that are present and to be formed on the surface of the contact plating. One of the main requirements for the electrical performance of electrical connectors is to establish and maintain a stable connector impedance. To achieve this, a metal contact interface is required to provide such inherent stability. The creation of such a contact interface requires that the surface film can be avoided or split upon contact mating. These two different options define the difference between a noble metal or a rare metal and a common metal.

4, the characteristics of the use of precious metal plating connector

The noble metal coatings (such as gold, palladium, and their alloys) are, to varying degrees, essentially free of the surface film. The metal contact that creates the interface for these coatings is relatively simple because it only requires the movement of the companion of the contact surface during mating. Usually this is easy to implement. In order to maintain the stability of the contact interface impedance, the connector design requires attention to maintaining the contact surface precious metals in order to prevent external factors such as contaminants, substrate metal diffusion and contact wear.

5, the connector uses the characteristics of ordinary metal coating

Ordinary metal coating, especially tin or tin alloy, its performance is naturally covered with a layer of oxide film. The role of tin contact plating, because this layer of oxide easily with the time to be destroyed, so that metal contacts can easily be established. The need for an electrical connector design is to ensure that the oxide film breaks when the connector is mated and that the contact interface is no longer oxidized during the life of the electrical connector. Reoxidation corrosion, in the wear and corrosion, is the most important performance degradation mechanism of tin contact plating. The silver contact plating is preferably treated as an ordinary metal coating because the coating is susceptible to corrosion by sulfides and chlorides. As the gas valve through the formation of the material is usually the nickel coating as a common metal.

Company Profile

Company Profile Company Culture

Company Culture Honor

Honor Corporate image

Corporate image Video Center

Video Center Connector series

Connector series Structural parts series

Structural parts series Machining series

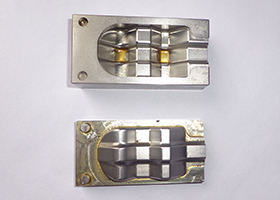

Machining series Mold Center

Mold Center Product information

Product information Corporate videos

Corporate videos Company News

Company News Industry News

Industry News Contact

Contact Feedback

Feedback Recruitment

Recruitment