Dongguan Taikang Electronic Technology Co., Ltd. was established in 2005 and is affiliated to Wenzhou-listed Yihua Group (stock code: 002897). In 2010, it was rated as a national high-tech enterprise. In 2011, the sales value was RMB 150 million.

The factory is located at the junction of Chang'an Xia and Humen Shutian, and on the edge of the Humen section of Tai'an Road; the factory covers an area of more than 130 mu, which is a typical garden-style industrial park; there are 9 buildings with 6 floors and 9 staff dormitories, which can accommodate 10,000 people. Accommodation; the living and working areas are scientifically arranged, and the supporting facilities in the park are complete, making it an ideal place to live and work. There are also affiliated companies such as Yizhao and Zhengde in the park; the buildings of the work building are constructed in a group of buildings, and the buildings are connected with extraordinary momentum. The company has formed a complete product development and manufacturing service platform, with product design, process design, mold design (stamping mold, injection mold and automation equipment) capabilities, and has the whole process of manufacturing and service capabilities. Mainly in the design, production, processing and sales of various types of precision electronic connectors, the products are widely used in consumer electronics, automotive, medical, security and other fields.

Product and customer introduction:

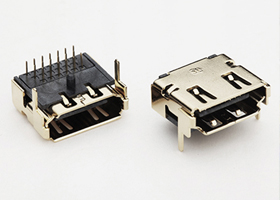

The company mainly produces HDMI Rec, HDMI Plug, Micro USB, Mini USB, Mini dp, Battery, SIM Card, RJ45 and other series of connectors, and with the development of the industry market, the customer's requirements continue to develop new products. It has won the trust of many domestic and foreign manufacturers, such as Molex, Amphenol, FCI, Sharp, Sanyo, Panasonic, ZTE, TCL, Skyworth, Hisense, Quanta, AOC, etc. The company actively expands international customers, and has established sales offices and agents in Taiwan, South Korea, the United States, Turkey, Europe and other places.

Enterprise honor: The company has successfully passed ISO9001:2008 quality management system, ISO14001:2004 environmental management system, ISO/TS16949:2009 automobile Quality management system, IECQ QC080000:2012 Process Hazardous Substance Management System and other certifications. Member of industry associations such as HDMI, USB, Diiva, etc.

◈ In April 2005, Dongguan Taikang Electronic Technology Co., Ltd. was established;

◈ In May 2008, won the title of HDMI Association Member;

◈ In October 2008, successfully passed ISO9001:2000 & ISO14000:2004 certification;

◈ In May 2009, won the title of "Guangdong Private Technology Enterprise";

◈ In March 2010, won the title of "Director Unit" of the 4th Council of Dongguan Private Enterprise Association;

◈ In December 2010, won the title of "Guangdong High-tech Enterprise";

◈ In April 2011, won the title of "Dongguan Patent Cultivation Enterprise";

◈ November 2011, certified by SONY Green Partner;

◈ January 2012, certified by BV.

◈ Passed ISO/TS16949:2009 automotive quality management system in May 2012.

◈ Passed IECQ QC080000:2012 Process Hazardous Substance Management System in July 2015.

Corporate Vision:

To become a first-class connector manufacturer, creating value for customers, employees and society.

Dongguan Taikang Electronic Technology Co., Ltd. strives to be proactive in terms of quality without defects, brand building, innovative research and development, etc. Our company currently has a place in the private connector industry. Our 3-year strategic goal is to enter the top 3 domestic private connector manufacturers. I believe that in the near future, Taikang will become a bright pearl among Chinese connector manufacturers!

Advantages and disadvantages compared with manufacturers in the same industry:

1. Fully equipped hardware. Has a full set of connector production capabilities - mold, stamping, injection molding, manual assembly line, automated assembly machine, product testing and testing, etc.

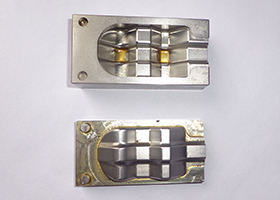

The mold equipment includes a complete set of processing equipment such as brand optical grinder, coordinate grinder, high-speed CNC, EDM, wire cutting, milling machine, 40 stamping equipment, 30 injection molding equipment (imported brands: Kyori, Fanuc, Nissei, etc.)

40 manual production lines, 30 automatic assembly machines (a number of automated flexible production equipment are being independently developed, and fully automated production lines for product parts input, assembly, testing, and packaging are gradually introduced), as well as complete laboratory equipment (with complete connectors in the connector industry. testing and verification capabilities).

2. Completely independent research and development strength and strong engineering capabilities. Engineering development, product design, mold design, fixture design and automatic machine design team of more than 40 engineers. Can provide integrated solutions for connector products. The company is introducing the PLM system and has established a standard R&D system.

3. Have a complete sales team and the ability to integrate sales resources. The company actively expands international customers and has established strategic cooperative relations with many domestic large customers. Taikang's parent company, Yihua Group, is preparing to go public, and the sales resources of each branch are integrating with each other and unifying the sales platform.

4. Build a complete internal management and manufacturing system. The company has implemented ERP system and mold management system. The manufacturing system is gradually optimizing the production process and equipment improvement, and fully introducing modern IE and lean production. Improve quality, environment and other management systems according to business development. Process batch pass rate is high.

5. Healthy corporate culture and human resource management. The company has attracted a large number of high-quality industry talents. The managers/supervisors and key engineers of each department have rich industry work experience in various large foreign or domestic enterprises in the connector field. Establish an apprenticeship training mechanism within the enterprise. For technicians and some engineer positions, the apprenticeship training promotion + external recruitment mechanism is adopted. The company and external consultants have developed a complete set of performance appraisal management systems. Our goal is to become a standardized enterprise that is respected by society and loved by employees.

Disadvantages: The current product line is slightly single, with HDMI and MicroUSB series accounting for 70%. In addition to expanding consumer electronics and communication products, the company has developed automotive connector products and is preparing to enter the medical connector product industry in 1-2 years.

Company Profile

Company Profile Company Culture

Company Culture Honor

Honor Corporate image

Corporate image Video Center

Video Center Connector series

Connector series Structural parts series

Structural parts series Machining series

Machining series Mold Center

Mold Center Product information

Product information Corporate videos

Corporate videos Company News

Company News Industry News

Industry News Contact

Contact Feedback

Feedback Recruitment

Recruitment