People in the choice of connector, the first will take into account the cost of control, the other is on the high-quality, high stability, as well as the connector itself design features. To avoid the electronic designers in the design process underestimated the importance of the connector, due to small losses, Dongguan City Taikang Electronic Technology Co., Ltd. specializes in the connector of the innovative design, to provide you with some reference:

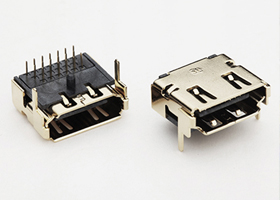

First: double rod design ideas. In the connector series, double-bar design ideas are consistent throughout. Image to say, double-pole design can be described as "double-edged sword." The optimized terminal design accommodates high-speed signal transmission, providing higher directional tolerances. In terms of inductance, capacitance, impedance, etc., double-pole terminals are smaller than box-type terminals for high-speed applications and are optimized for minimum discontinuities. The dual-pole design allows multiple connectors to be placed on a single circuit board without plugging or short-circuiting, without the need for a large number of signals on a single connector. Simple alignment of the double rods saves space, makes the connector smaller, and simplifies the detection of the solder pins. For example, put in a board 12. While reducing rework costs. Practical applications such as telecommunications end-user equipment.

Second: the assembly process without bow pin design. Traditional stamping due to improper handling can cause bending or deformation of the pin, bending process will cause capillary cracks, from the long-term product is not desirable, but also affect the circuit performance and cost. The design of some of the connector Taikang used on the direct bending angle, stamping terminal bending process can avoid the capillary cracks caused to ensure that the complete mechanical and electrical connections. Pin coplanarity of 100%, control to tolerance ± 0.05mm, 100% of the surface-mount pin coplanarity testing to ensure the reliability of the circuit board assembly process to ensure a good welding, improve product good rate and reduce costs. And improve the rigidity of the right-angle connector to prevent damage due to improper operation of the connector, with "unbreakable" to describe a very appropriate. Particularly suitable for inkjet printer controller, module interface.

Third: high retention of surface mount design. For some connector products, it is generally accepted that the retention of the board is poor. Is the surface mount terminal PCB retention is lower than the through-hole termination? The answer is: not necessarily. Through the design improvement can effectively improve the retention of PCB. If the welding bracket, surface-attached pin hole (micropore), a large pad on the three areas can increase the retention of superposition. In fact, even the I / O connector can also be used surface mount pin. This can be vividly compared to "ground to take root." Such as X-ray machines, ultrasonic scanners, and robotic Ethernet switches.

Fourth: rugged design. To determine the reliability of the connector, while allowing the use of flat block crimping tool, the plate fixed to the shell to improve the ruggedness, to achieve better manufacturing process and increase production. To sum up in one word is "rock-solid." Specific applications such as positron emission tomography, railway vehicles, embedded systems.

Fifth: high current, small spacing design. With the automotive electronics, consumer electronics miniaturization requirements, need to consider the high current, small spacing design.

Sixth: advanced locking design. ERNI double-lock design to meet different needs, positive shock for the strong shock applications, it is ideal for automotive and subway applications, the friction lock is designed for general vibration applications. Double lock double safety insurance to ensure a reliable connection, and on-site demolition (repair / replacement) cable does not require special tools. Suitable for monitoring devices, LED lights and other design.

Connectors in the whole electronic system design plays a role in the whole body, engineers in the choice of electronic components not only need to pay attention to chip technology, also need to focus on the choice of peripheral devices, so as to allow the system to run handy, play More effective.

Company Profile

Company Profile Company Culture

Company Culture Honor

Honor Corporate image

Corporate image Video Center

Video Center Connector series

Connector series Structural parts series

Structural parts series Machining series

Machining series Mold Center

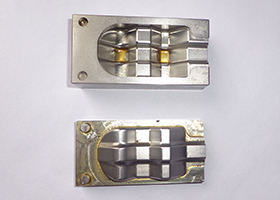

Mold Center Product information

Product information Corporate videos

Corporate videos Company News

Company News Industry News

Industry News Contact

Contact Feedback

Feedback Recruitment

Recruitment