The design focus of connector Housing

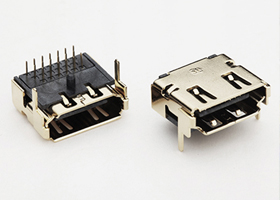

Housing Housing is the main structure of the connector, for other parts of the connector positioning space, in addition, it also plays for the connector insulation between the conductor parts. Therefore, it requires designers to design the connector Housing in the process of planning must be a good size requirements and molding, the other election materials to take into account the customer's process conditions, the application needs to be limited to the mold segment into the glue mouth, On the surface.

The connector housing is the main body member of the entire connector, and the other parts are assembled to the connector body. It determines the appearance of the connector size, to confirm its structural strength can withstand the end-user normal use of the destructive force or customer test specifications specified (for example: the direction of the force required to apply an external cable, can not see the damage; The installation of screws, the application of appropriate torque can not cause damage).

Since it is the main component, the natural shoulder the responsibility of positioning the parts, so with other parts of each part of the size and tolerance (including geometric tolerances) need to be appropriate. Important features (for example, the hole in the terminal, the width of the drawer) are determined by a single die, and the die can be machined by the grinder, the tolerance of +/- 0.02 mm can be set to ensure the function. Other as orthogonality, flatness, contour and other geometric tolerances should be properly applied before ensuring functionality.

The terminal in addition to the connector Housing to do space on the positioning, it must rely on the connector Housing on its holding force to produce terminal mechanical behavior on the boundary conditions, and then in the male and female docking to produce the appropriate positive force. Therefore, the size and shape of the interference section between the terminal and the connector Housing must be handled very carefully. Appropriate terminal barb shape and the amount of interference in order to get the appropriate terminal retention, and not due to interference caused by excessive Housing Housing deformation or rupture.

In the electrical function, the connector Housing shoulder the insulation between the various conductor parts, the general engineering plastic impedance value, as long as the injection molding done to do the thickness of the subsequent processing without causing structural damage, the plastic insulation resistance And withstand voltage effects can meet the specifications. Only in the case of very hygroscopic materials or when the terminals are pushed in to cause the breakage of the plastic barrier, the insulation resistance or the withstand voltage of the plastic part may occur. Otherwise, most of the worry is that the conductor exposed to the plastic The insulation effect between the parts, because the insulation effect of the air is far better than the engineering plastics.

In addition to considering the above-mentioned functionalities, the housing design of the connector housing also requires consideration of the manufacturability of the injection molding, too thick or too thin or uneven thickness, and too severe shrinkage, too thin, Then the flow of liquid plastic filling the front of the imbalance can easily lead to cooling warp. Usually the system is responsible for drawing a good part with the functionality of the model to die mold design engineers, mold engineers will be determined by the experience of where to add what kind of escape material to improve the formability, but if the flesh of the original design of the actual The size has been very small and the proportion of the case of the thickness of the difference, the mold engineers can not escape the adjustment by the material, the workers should avoid such a situation. Mold engineers to do a good job after the planning of escape material should be confirmed with the workers after the structural strength of escape material is still in line with functional requirements, confirmed and then mold flow analysis and mold opening action.

Plastic material is simply divided into high-temperature materials and low-temperature materials, materials, heat distortion temperature and general SMT process temperature compared to distinguish between high-temperature materials and low temperature material. General use of the connector are subject to SMT high temperature process, it must use high temperature material. In some cases, sufficient space must be provided on the upper surface of the connector Housing for the customer to use for the automatic insertion of the vacuum suction area, so avoid the placement of glue points or mold joint lines in order to avoid vacuum nozzle failure.

Housing housing design should pay attention to the bottom, to avoid the pressure on the PCB painted solder paste, so as to avoid short-circuit between the pad.

Company Profile

Company Profile Company Culture

Company Culture Honor

Honor Corporate image

Corporate image Video Center

Video Center Connector series

Connector series Structural parts series

Structural parts series Machining series

Machining series Mold Center

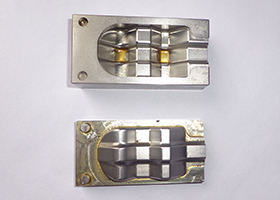

Mold Center Product information

Product information Corporate videos

Corporate videos Company News

Company News Industry News

Industry News Contact

Contact Feedback

Feedback Recruitment

Recruitment